Заявка

на обратный звонок

Отправляя заявку, Вы соглашаетесь на обработку Ваших персональных данных.

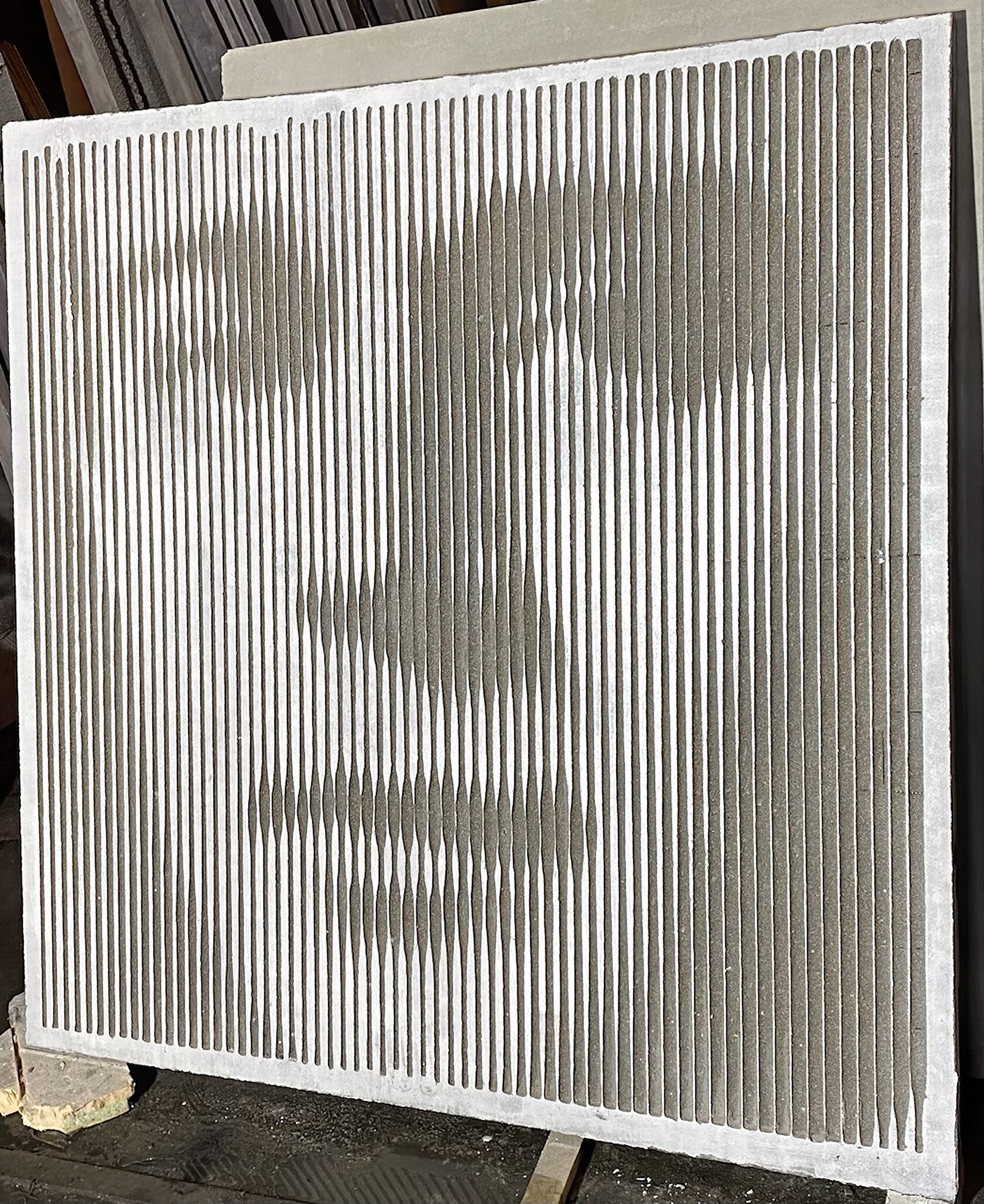

Photo-engraved concrete

нprinted by a 3D plotter without the use of matrices

printed by a 3D plotter without the use of matrices

an absolute BREAKTHROUGH in the production of PHOTO-ENGRAVED concrete

Innovative technology opens up new opportunities

The technology for the production of photo-engraved concrete by "CHIOS Engineering" opens up new opportunities for the creative use of one of the most premium types of facades.

Prior to the invention of our technology, the only sustainable photo-engraved facades were offered by the companies that use expensive matrices for their purposes, which made the use of photo-engraved concrete in house building extremely limited.

Our company has developed an innovative way to print photo-engraved concrete facades up to the size of 11 meters x 4.5 meters on a 3D plotter and thus made photo-engraved facades as accessible as other types of facades made of architectural concrete. Such a breakthrough in technology makes it possible to freely use photo-engraved concrete in facade solutions for construction projects around the world!

Prior to the invention of our technology, the only sustainable photo-engraved facades were offered by the companies that use expensive matrices for their purposes, which made the use of photo-engraved concrete in house building extremely limited.

Our company has developed an innovative way to print photo-engraved concrete facades up to the size of 11 meters x 4.5 meters on a 3D plotter and thus made photo-engraved facades as accessible as other types of facades made of architectural concrete. Such a breakthrough in technology makes it possible to freely use photo-engraved concrete in facade solutions for construction projects around the world!

Examples of implemented projects with photo-engraved concrete facade solutions in Europe and the USA:

what was before us?

Before the launch of our technology to produce photo-engraved concrete two technologies were used:

- One method was to pour concrete into rubber matrices, the cost of one unit of which starts from €600 per square meter.

- Another method was to create the image through the use of an inhibitor that slows down the setting of the concrete. This solution leads to low frost resistance and surface strength, therefore pieces produced by this technology can be used solely for interior decoration.

«CHIOS» technology advantages

Based on the «CHIOS» technology, photo-engraved concrete is produced on a 3D printing plotter by applying a soluble paste to the platform (see the detailed description here). This provides the following benefits:

- greater diversity in the variability of facades and hidden joints of photo-engraved concrete panels as a 3D plotter prints any images in any size and quantity, whereas the matrix is limited to one visualization.

- high speed of photo-engraved concrete production. No more waiting for long-term production of matrices, we print photo-engraved concrete at a speed of 4 meters per minute.

- reduction of negative impact on the environment. The only waste from the production of "CHIOS" photo-engraved concrete panels is a water-soluble paste, which is safe for the planet's ecology.

«Photo-engraved concrete is an opportunity to leave your mark on history and capture history in architecture for centuries»

Video review of photo-engraved concrete production using water-soluble paste and 3D printing plotterStep 1: Upload the image to a computer, digitize and optimize the image to reproduce it. Step 2: Divide the color tones into 256 shades of gray Step 3: Generate a processing file based on certain gray values. The file contains print commands for the 3D plotter software. The print commands tell the 3D plotter how to print the photo on the surface. The commands include a variety of fine grooves that vary in texture from fine to coarse to create different shades of gray, first identified from individual color tones. Step 4: Apply a water-soluble paste to the platform to form a facade pattern according to a given file. Step 5: Fill the panel. Step 6: Lift the panel and rinse the water-soluble paste with water. |

*click to watch the video

*click to watch the video

Hinged facade panel made from photo-engraved concrete with a portrait of Yesenin

Some of the possible visualizations for photo-engraved concrete

Photo-engraved concrete is made to revive any imagination of the architect and the customer

Construct unique photo-engraved concrete buildings around the world with us!

Leave a request for the purchase of photo-engraved concrete panels and our manager will contact you.

Оставить заявку

на панели из фотобетона

Отправляя форму, Вы даёте согласие на обработку своих персональных данных.

The facade of any construction object is a business card of the architect and developer who own the project.

The facade can also become a landmark of the whole city, and, depending on the location of the construction object, its appearance may be of high significance.

The use of a facade made of photo-engraved concrete allows the architect to play with visualization and create thin threads of light and shadow dance on the building.

The possibilities of using photo concrete are almost limitless, since one can use any image to create their own facade.

The facade can also become a landmark of the whole city, and, depending on the location of the construction object, its appearance may be of high significance.

The use of a facade made of photo-engraved concrete allows the architect to play with visualization and create thin threads of light and shadow dance on the building.

The possibilities of using photo concrete are almost limitless, since one can use any image to create their own facade.

Contacts

Russia, Moscow, Presnenskaya embankment 12/2

By sending the request, you consent to the processing of personal data and agree to the privacy policy